In the fast-paced world of construction, precision is everything. From towering skyscrapers to sprawling highways, every project begins with a foundation of accurate measurements. At True North Positioning, a leader in construction data management and geospatial solutions with over 20 years of experience, we know that survey control points are the backbone of any successful construction project. These reference markers ensure that every element of a build aligns perfectly with the design, preventing costly errors and delays. In this blog, we explore why survey control points are critical to construction success and how True North Positioning’s expertise can elevate your project.

What Are Survey Control Points?

Survey control points are fixed, precisely measured markers on a construction site with known horizontal and vertical coordinates, often tied to a global or local coordinate system. Established using advanced tools like GNSS (Global Navigation Satellite Systems), total stations, or 3D laser scanners, these points serve as the reference framework for all surveying and construction activities. They can be physical markers like survey nails, hubs, or permanent benchmarks, strategically placed to guide the layout of foundations, columns, roads, and utilities. According to industry insights, control points are the “skeleton” of a project, ensuring every component is positioned correctly from start to finish.

Why Survey Control Points Matter

Without accurate survey control points, construction projects risk misalignment, structural flaws, and budget overruns. Here’s why they’re indispensable:

1. Ensuring Precision and Alignment

Survey control points provide a consistent reference for all measurements, ensuring that structures are built exactly as designed. For example, in a high-rise project, a single misaligned control point could lead to walls, floors, or columns being off by centimeters, compromising structural integrity.

Real-World Impact: On a bridge construction project, control points ensure that abutments built miles apart align perfectly when connected by a steel deck. True North Positioning uses GNSS and total stations with 1–3 mm accuracy to establish control points that meet such stringent requirements.

Benefit: Precise control points eliminate cumulative errors, where small mistakes compound into major discrepancies, saving time and rework costs.

2. Preventing Costly Errors and Delays

Inaccurate control points can derail a project, leading to misaligned foundations, utilities, or property boundaries. Industry data shows that surveying errors contribute to 10–15% of construction delays, with rework costs averaging 5% of a project’s budget.

Scenario: If a control point is disturbed during excavation, subsequent measurements may be off, causing a building’s footprint to encroach on a property line. This could halt construction for legal reviews or require demolition.

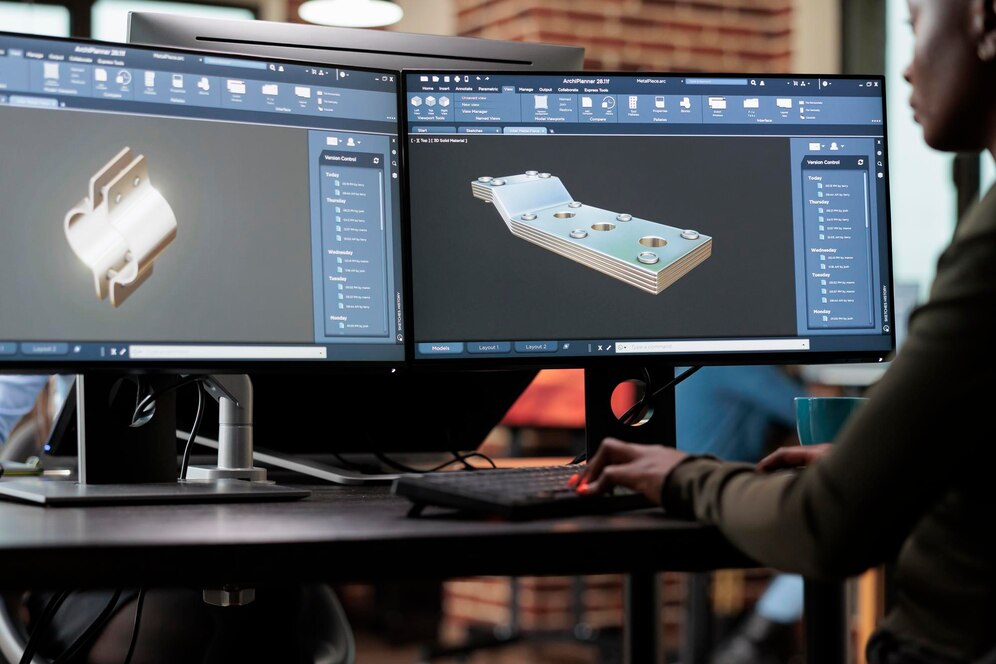

Solution: True North Positioning employs rigorous verification processes, checking control points against original survey data throughout the project. Our use of BIMand CAD integration ensures real-time clash detection, catching errors before they escalate.

Tip: Place control points in stable, accessible locations outside construction zones, such as concrete pads, to avoid disturbance.

3. Supporting Complex and Large-Scale Projects

Large projects, like industrial facilities or transit systems, require a robust control network to coordinate multiple trades and phases. Control points link all elements to a unified coordinate system, ensuring compatibility across disciplines.

Example: In a multi-building campus development, control points allow architects, engineers, and contractors to work from the same reference, preventing mismatches between structural and utility layouts.

Benefit: A well-distributed control network, with at least 4–6 points surrounding the site, supports scalability and precision, especially for projects spanning large areas or requiring georeferencing to state or national grids.

True North Advantage: Our 3D laser scanning services tie control points to real-world coordinates, delivering accurate BIM models for complex projects, with over 700 million square feet scanned across North America.

4. Enabling Advanced Technology Integration

Modern construction relies on technologies like GPS, drones, and machine control systems, all of which depend on accurate control points. For instance, GNSS-equipped machinery uses control points to guide grading or piling with sub-centimeter precision.

Application: In heavy civil construction, ground control points (GCPs) ensure aerial drone surveys align with site plans, critical for earthwork calculations. True North Positioning’s expertise in georeferencing ensures GCPs are optimally placed for visibility and stability.

Benefit: Control points enhance efficiency by enabling real-time data integration, reducing manual staking and speeding up workflows.

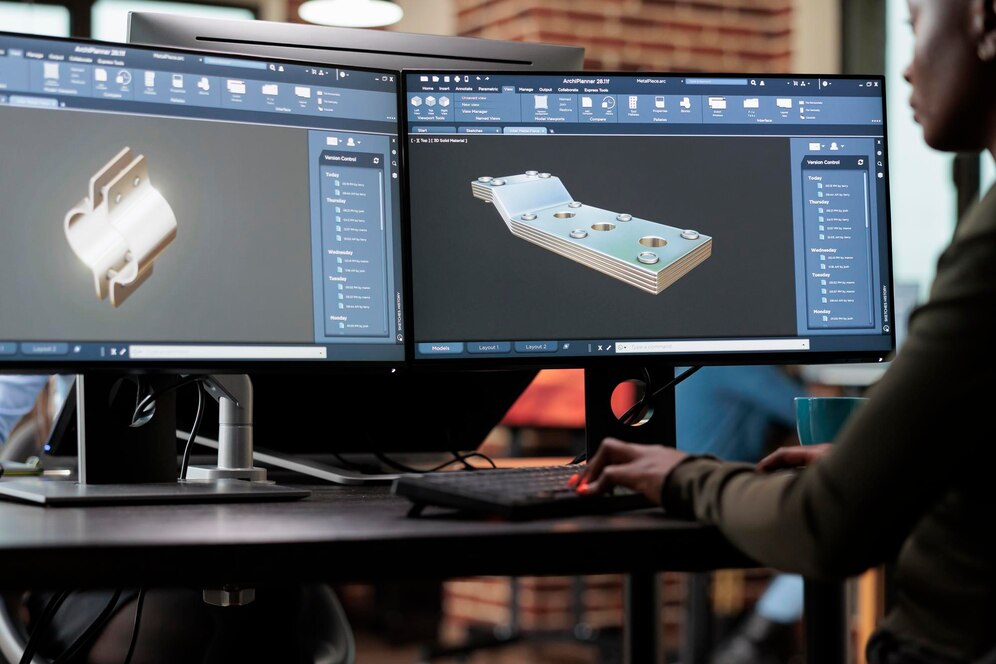

Our Tools: We leverage Trimble R12i GPS and Leica total stations, offering angular accuracy of 1–3 seconds, to establish control networks that support cutting-edge software like Autodesk Revit.

5. Ensuring Compliance and Long-Term Reliability

Control points tie projects to legal boundaries, property lines, or national coordinate systems (e.g., Canada’s NAD83), ensuring compliance with regulations and facilitating future expansions. They also serve as benchmarks for as-built surveys, verifying that construction matches design intent.

Scenario: For a pipeline project, control points ensure segments align over long distances, meeting environmental and safety standards.

Benefit: Accurate control points reduce legal disputes over boundaries and provide a reliable reference for maintenance or retrofitting years later.

True North Commitment: Our licensed surveyors verify control points against geodetic standards, guaranteeing compliance and durability for projects across Ontario and beyond.

Best Practices for Establishing Control Points

To maximize their effectiveness, survey control points must be strategically planned and maintained:

Site Analysis: Conduct a topographic survey to identify stable, visible locations free from obstructions like trees or buildings.

Quantity and Distribution: Use a minimum of 4 points, evenly spread around the site’s perimeter, to create a closed traverse. More points enhance redundancy if some are disturbed.

Technology: Use GNSS for rapid setup and total stations for high-accuracy projects like bridges or tunnels. Verify coordinates with a closed level run or resection.

Maintenance: Monitor points throughout construction to ensure they remain undisturbed, re-surveying if necessary.

Documentation: Provide contractors with X, Y, Z coordinates in formats like CAD, CSV, or TXT for seamless integration.

True North Tip: Save time by requesting a comma-delimited text file of primary control coordinates from your surveyor to reduce transcription errors when loading into GPS or total stations.

Why Partner with True North Positioning?

At True North Positioning, we understand that survey control points are the foundation of construction success. Here’s how we ensure precision and reliability:

20+ Years of Expertise: Our team has managed control surveys for projects ranging from commercial developments to infrastructure, delivering measurable results.

Advanced Technology: We use GNSS, RTK systems, and 3D laser scanning to establish control points with sub-millimeter accuracy, integrated with BIM and CAD workflows.

Canadian Focus: Based in Ontario, we align control points with NAD83 and local grids, ensuring compliance with Canadian regulations.

Comprehensive Support: From site analysis to ongoing monitoring, we provide end-to-end survey solutions, minimizing risks and maximizing efficiency.

Client-Centric Approach: Our tailored consultations and transparent data delivery empower contractors to stay on schedule and budget.

Testimonial: “GP Custom Metals Inc. had an excellent experience working with True North Positioning for site measurement and surveying on our Terra Hill and York University projects. Their team demonstrated outstanding precision, professionalism, and efficiency, ensuring accurate results that contributed to the smooth execution of our work. Their attention to detail and commitment to accuracy make them a reliable partner in the industry. We highly recommend True North Positioning and look forward to future collaborations!” – Omid Jokar

Build with Confidence

Survey control points are the unsung heroes of construction, ensuring precision, efficiency, and compliance from groundbreaking to completion. By establishing a robust control network, you mitigate errors, streamline workflows, and deliver projects that stand the test of time. At True North Positioning, we’re committed to setting the standard for survey accuracy, leveraging cutting-edge technology and decades of experience to make your project a success.

Ready to lay the foundation for your next project? Contact True North Positioning at truenorthpositioning.com or call (416) 562-4559 for a free consultation. Let’s build with precision, together.